Custom Design Solutions:

We specialize in providing custom jig and fixture design solutions tailored to the unique needs of each client. Whether it's designing fixtures for machining, welding, assembly, or inspection, we ensure that the design meets all functional and performance requirements. Our custom solutions help improve production efficiency and accuracy.

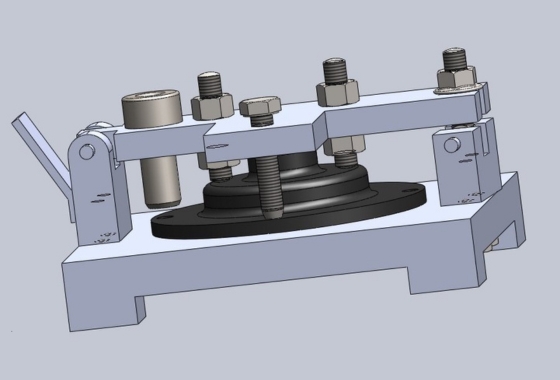

Design and Prototyping:

Our team uses advanced CAD software to create detailed designs for jigs and fixtures. These designs are used to develop prototypes that allow us to test and validate the design before full-scale production. Prototypes help identify any issues and ensure that the jig or fixture performs as intended.

Integration with Manufacturing Processes:

Jigs and fixtures need to integrate seamlessly with existing manufacturing processes and equipment. We ensure that our designs are compatible with the client's production setup and provide support for any necessary adjustments or modifications. This integrated approach helps ensure smooth and efficient production.

Quality Assurance:

Quality assurance is a key component of our jig and fixture design services. We implement rigorous quality control measures to ensure that the jigs and fixtures meet all specifications and industry standards. Our team conducts detailed inspections and tests to verify that the design is accurate and reliable.

Applications and Benefits:

Our Jig and Fixture Design services are applicable to various industries, including automotive, aerospace, and manufacturing. The benefits include improved precision, consistency, and efficiency in production processes. By providing high-quality jigs and fixtures, we help clients achieve their manufacturing goals and enhance their production capabilities.